The Ultimate Guide to Hiring Commercial Roof Coating Contractors

Why Commercial Roof Coating Contractors Are Essential for Building Protection

Commercial roof coating contractors apply protective liquid membranes to existing roofs, extending their lifespan by 10-20 years while improving energy efficiency and waterproofing. When hiring, prioritize licensed professionals with proven local experience, manufacturer certifications, and detailed proposals.

Key Contractor Qualifications:

- Licensing and Insurance: Verify active licenses and full liability coverage.

- Manufacturer Certifications: Confirms training on specific coating systems.

- Local Experience: Look for a portfolio of completed projects in your climate.

- Detailed Proposals: Should specify surface prep, coating type, thickness, and warranty.

- Safety Programs: Ensure OSHA compliance and worker safety protocols.

An aging commercial roof with minor leaks or rising energy bills presents a dilemma: is a costly replacement necessary? Often, the answer is no. Commercial roof coating contractors offer a smarter alternative by applying a seamless, protective membrane that restores your roof’s performance for a fraction of the replacement cost and with minimal business disruption.

For building owners in Oregon, Southern Washington, and Northern California, the success of a roof coating depends on the contractor’s expertise. Proper surface preparation and correct application are critical for a coating that lasts two decades versus one that fails in a few years.

I’m Larry Sykes, Director of Sales and Marketing at Pressure Point Roofing. With over 38 years in the industry, I’ve helped countless building owners make informed decisions about extending roof life with restoration systems versus pursuing a full replacement.

Understanding Commercial Roof Coatings: A Smart Solution for Building Owners

Commercial roof coatings are liquid-applied membranes that cure into a seamless, durable, and protective skin for your building. These engineered polymer systems shield your roof from UV radiation, ponding water, and temperature extremes. When applied by professional commercial roof coating contractors, they create a waterproof barrier that prevents leaks and deterioration, adding years of reliable performance to your existing roof structure.

Coatings address the natural wear and tear on commercial roofs, such as minor leaks and surface degradation. For roofs that are structurally sound but showing age, coatings are often a smarter path than a full tear-off and replacement. You can learn more about common issues in our guide on What Causes Problems in Commercial Roofing Systems and weigh your options in Repair or Replace a Commercial Roof.

Signs Your Roof May Benefit from a Coating

Knowing when to call commercial roof coating contractors is key. Look for these clues:

- Minor Leaks: Small, isolated leaks can be effectively sealed with a coating, preventing them from escalating. Our article on a Leaking Commercial Roof explains how to identify these warnings.

- Aging Surface: General surface degradation, blistering, or superficial cracking indicates the protective layer is wearing thin. A coating can refresh the surface if the underlying structure is solid.

- Alligatoring: This pattern of interconnected cracks on asphalt-based roofs can be covered by a coating to prevent them from deepening, as long as the membrane below is intact.

- Faded Membrane: A chalky or graying TPO or EPDM roof has lost its reflectivity. A fresh coating restores both appearance and performance.

- High Energy Bills: If your HVAC system runs constantly in the summer, your roof may be absorbing heat. A reflective “cool roof” coating can significantly lower your building’s energy consumption.

Regular check-ups, like those in our Fall Commercial Roof Inspection guide, help identify these issues early.

Key Benefits of Roof Restoration

Choosing a coating over replacement is a smart investment with long-term dividends.

- Extends Roof Lifespan: A quality coating can add 10-20 years of service life to your roof, shielding it from environmental damage.

- Improves Energy Efficiency: Reflective “cool roof” coatings can lower roof surface temperatures, reducing HVAC workload and potentially cutting energy costs by up to 30% in peak months.

- Reduces Environmental Impact: Coating an existing roof avoids sending tons of old roofing material to landfills, making it a sustainable choice.

- Offers Potential Tax Advantages: A coating may qualify as a maintenance expense, offering immediate tax deductions. Energy-efficient systems may also be eligible for rebates. This is an important factor when Budgeting for a Commercial Roof Replacement.

- Causes Minimal Disruption: Unlike a loud and messy roof replacement, coating applications are quiet and cause little interference with your daily business operations.

Types of Roof Coatings and How to Choose the Right One

Not all roof coatings are the same, and choosing the right one is crucial for long-term success. The ideal coating depends on your existing roof material, local climate, and building use. Elastomeric coatings are the foundation of modern roof protection. These flexible, rubber-like materials expand and contract with temperature changes without cracking, which is essential for the varying weather in Oregon, Southern Washington, and Northern California. Silicone and acrylic coatings are the two most popular choices.

Silicone Roof Coatings

Silicone coatings are ideal when water is the primary concern. Their standout feature is ponding water resistance; they can withstand standing water for extended periods without breaking down. This makes them perfect for flat or low-slope roofs common in the Pacific Northwest. Silicone also has excellent UV stability, maintaining its flexibility and strength despite years of sun exposure. As a moisture-cured product, it can be applied in a wider range of temperatures, and a professional application typically lasts 10-15 years.

Acrylic Roof Coatings

Acrylic coatings are the top choice when energy efficiency is the priority. These highly reflective coatings excel as “cool roof” solutions, bouncing solar heat away from the building to lower indoor temperatures and reduce air conditioning costs. As water-based products, they are environmentally friendly but require specific temperature and humidity conditions to cure properly. Acrylics offer excellent UV resistance and are best suited for roofs with a slight slope that allows for proper water drainage, as they are not designed for prolonged ponding.

[TABLE] Comparing Silicone vs. Acrylic Roof Coatings

| Feature | Silicone Roof Coatings | Acrylic Roof Coatings |

|---|---|---|

| Ponding Water Resistance | Excellent (withstands prolonged ponding without degradation) | Poor (not recommended for areas with ponding water) |

| UV Resistance | Excellent (highly stable, maintains properties) | Good (protects against weathering, aging, and UV) |

| Durability | High (flexible, long-lasting) | Good (flexible, good for temperature fluctuations) |

| Flexibility | High (retains elasticity over time) | High (elastomeric, expands and contracts well) |

| Application | Moisture-cured (can be applied in wider temperature ranges) | Water-based (requires specific drying conditions) |

| Environmental Impact | Good (extends roof life, reduces waste) | Good (often lower VOCs, extends roof life, reduces waste) |

Substrates Suitable for Coating

One of the biggest advantages of roof coatings is their versatility. Experienced commercial roof coating contractors can apply them over most existing roof materials, provided the underlying structure is sound.

Coatings can be applied to:

- Metal roofs: To seal fasteners, prevent rust, and add reflectivity.

- EPDM (rubber): To improve reflectivity and extend service life.

- TPO and PVC: To improve UV resistance and add another layer of protection.

- Modified Bitumen and Built-Up Roofs (BUR): To restore waterproofing and UV protection on asphalt-based systems.

The critical requirement is that the roof must be structurally sound. A thorough inspection by a qualified contractor is always the first step to ensure your roof is a good candidate for restoration.

The Roof Coating Process and Long-Term Performance

A successful roof coating project is a systematic process where shortcuts are not an option. The long-term performance of a coating depends heavily on what happens before the material is applied. Professional application by experienced commercial roof coating contractors ensures the system can withstand our region’s weather, from heavy Oregon rains to intense California sun. For ongoing protection, follow our Tips for Commercial Roofing Maintenance.

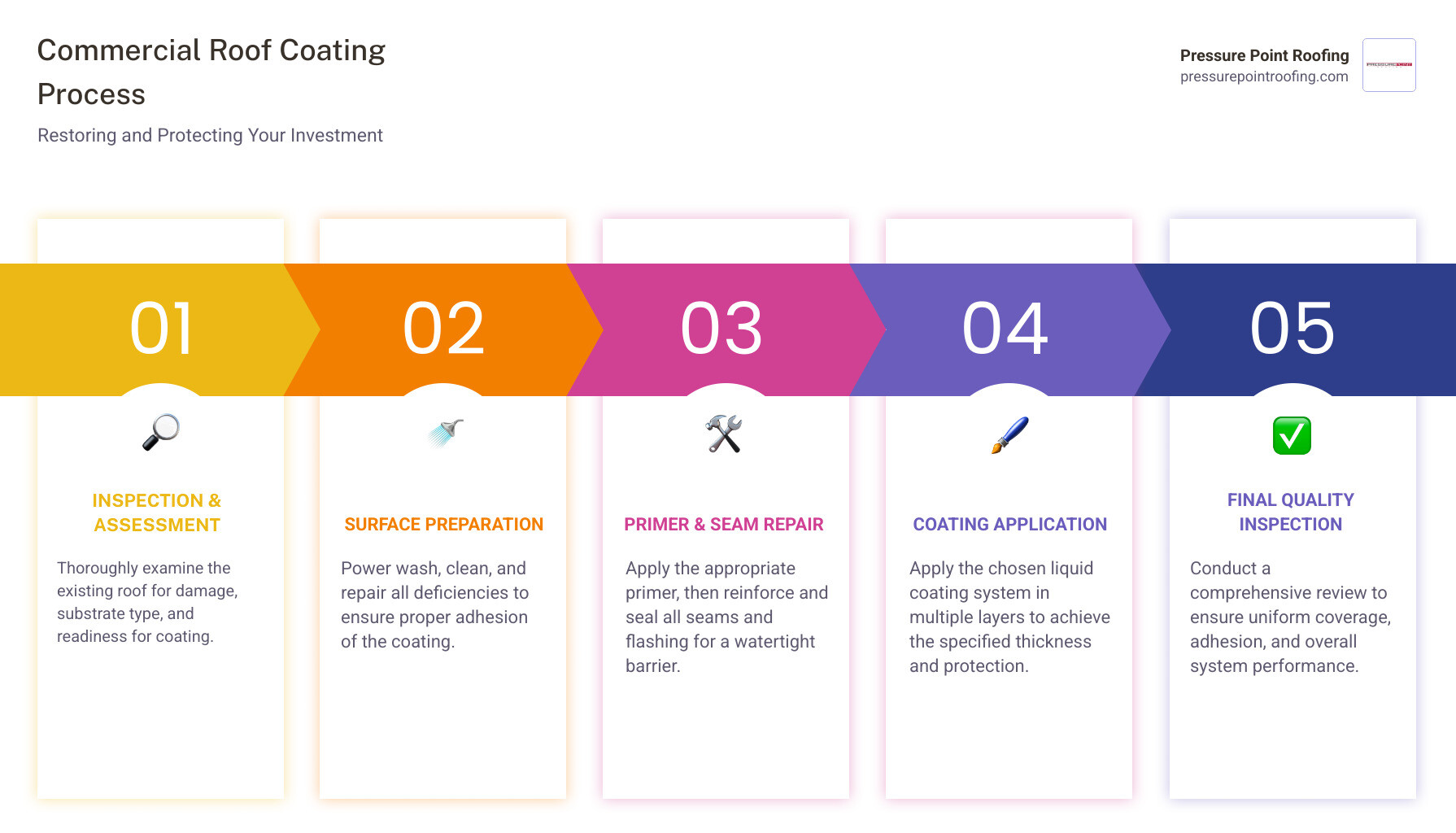

The Step-by-Step Application Process

Every successful project follows a methodical sequence for optimal adhesion and performance.

- Roof Inspection: A thorough examination identifies repairs, assesses structural integrity, and confirms the roof is a good candidate for coating.

- Power Washing and Cleaning: This critical step removes all dirt, algae, and contaminants that could prevent proper adhesion. A clean surface is essential for a lasting bond.

- Primer Application: When required, a primer acts as a bonding agent between the existing roof and the new coating, ensuring a strong chemical connection.

- Seam and Flashing Repair: All seams, penetrations, and flashings are reinforced with specialized sealants and fabrics to create a completely watertight system.

- Coating Application: The coating is applied in multiple layers, often by spray or roller, to achieve the manufacturer’s specified thickness for even, durable coverage.

- Final Inspection: Once cured, a final quality check verifies that the application meets all specifications, ensuring your roof is fully protected.

Lifespan and Maintenance for Your Coated Roof

A professionally applied coating can extend your roof’s life by 10-20 years. Lifespan is influenced by UV exposure, the amount of foot traffic, and, most importantly, the quality of the initial installation. Regular maintenance is key to maximizing this lifespan. Annual inspections, keeping the roof clear of debris, and ensuring drains are clean will catch small issues before they become big problems. Proactive care, as detailed in our guide to Prevent Roof Rot with Regular Roof Maintenance, protects your investment. Before winter, review our tips for Winter Weather Commercial Roof preparation.

Performance in Harsh Weather

Coatings are designed to withstand extreme conditions.

- Hail Resistance: Coatings absorb impact energy, protecting the underlying membrane from punctures during typical hailstorms. This is valuable in areas prone to events like those discussed in Commercial Roofing Hail Damage in Central Point OR.

- Heavy Rain Protection: The seamless, waterproof barrier prevents water intrusion, even during prolonged downpours. Silicone coatings are especially effective against ponding water.

- Wind Uplift Resistance: By bonding the roof into a single, unified system, coatings reduce the risk of wind catching and lifting membrane sections during severe storms.

- UV Degradation: Coatings act as a shield against the sun’s damaging UV rays, preventing the underlying material from becoming brittle and cracked.

If severe weather does cause damage, a quick response is critical. Our team provides Emergency Roofing Repair in Jacksonville OR and throughout our service area.

How to Hire the Best Commercial Roof Coating Contractors

Choosing the right commercial roof coating contractors is the most important decision you’ll make for your restoration project. The right team ensures your roof protects your building for decades, while the wrong one can lead to premature failure. Knowing what to look for simplifies the selection process.

What to Look for in a Commercial Roof Coating Contractor

Hiring a contractor is like building a team; you need professionals with expertise, accountability, and a proven track record.

- Licensed and Insured: This is non-negotiable. Verify current state licenses and comprehensive liability and worker’s compensation insurance to protect your property.

- Manufacturer Certifications: These show a contractor has specialized training in applying specific coating systems correctly, which is often required for a valid warranty.

- Local Experience: A contractor familiar with the climate in Oregon, Southern Washington, and Northern California knows which systems perform best locally. At Pressure Point Roofing, our 35 years of local experience means we’ve handled nearly every roofing scenario our region offers.

- Positive Reviews and References: Look for detailed reviews from other commercial property owners. Ask for references from projects similar to yours and follow up with them.

- Detailed Proposal: A professional proposal outlines every step, including surface preparation, the specific product used, application thickness, and warranty coverage. Vague proposals are a red flag.

- Safety Protocols: A commitment to OSHA compliance and safety protects workers, your property, and your tenants during the project.

The Importance of Technical Expertise

The best commercial roof coating contractors have deep technical knowledge and strong relationships with material manufacturers. This expertise ensures they select the right coating system for your specific roof and climate challenges. They stay updated on the latest product formulations and application best practices, which is crucial for quality control and ensuring every step is followed precisely to validate your warranty.

Understanding Financing and Tax Incentives

A roof coating is a significant investment, but financial options can make it more manageable.

- Tax Deductions: Under Section 179, some roof coating projects may qualify as a maintenance expense, allowing for an immediate tax deduction. Always consult your tax professional to confirm eligibility.

- Energy Rebates: Reflective “cool roof” systems often qualify for rebates from utility companies or local governments, offsetting some of the initial investment.

- Insurance Claims: If your roof was damaged in a storm, experienced contractors can help document the damage and provide detailed estimates for your insurance claim.

- Financing Options: Many reputable contractors offer financing plans to help you protect your building now without depleting capital reserves.

Frequently Asked Questions about Commercial Roof Coatings

Building owners considering roof coatings often have similar questions. Here are clear, concise answers to the most common inquiries we receive.

Why should I hire professional commercial roof coating contractors?

Professional application is the single most important factor in a coating’s success. While it may seem like a paint job, it’s a complex process. Professionals provide:

- Expertise: They know how to assess your roof and choose the right system for your substrate and our regional climate.

- Proper Surface Preparation: This critical step, including cleaning and repairs, ensures the coating adheres correctly and doesn’t peel or fail.

- Warranty Compliance: Manufacturers typically only honor their warranties when their products are applied by certified contractors according to strict specifications.

- Safety: Professional crews are insured, follow OSHA protocols, and work safely at heights, protecting their team and your property.

- Access to Quality Materials: Contractors use commercial-grade products that offer superior durability compared to anything available at a retail store.

How long does a commercial roof coating last?

A properly applied coating typically adds 10-20 years to your roof’s life. The exact lifespan depends on several factors, including the coating thickness, the quality of the installation, and the local environmental factors like UV exposure and foot traffic. The most critical factor is the skill of your commercial roof coating contractors. Regular maintenance, such as annual inspections and keeping the roof clean, is also essential for maximizing longevity. Our Tips for Commercial Roofing Maintenance guide offers practical advice.

Can any commercial roof be coated?

No, not every roof is a good candidate. The most important requirement is that your roof must be structurally sound. Coatings are restoration systems, not structural repair solutions; they cannot fix widespread rot or a failing substrate. However, they are highly versatile and work well over most common roof types, including metal, EPDM, TPO, PVC, and modified bitumen. A professional inspection is the only way to determine if your roof is suitable. An experienced contractor will assess the roof’s integrity to ensure a coating will deliver the long-term performance you expect. If your roof has major damage, explore your options in our article, Repair or Replace a Commercial Roof.

Conclusion: Protect Your Investment with a Professional Roof Coating

Your commercial roof is a valuable asset. Protecting it with a professional roof coating is a smart, cost-effective alternative to a full replacement. As we’ve covered, commercial roof coating contractors can extend your roof’s life by 10-20 years, improve energy efficiency, and create a seamless waterproof barrier.

The benefits are practical and significant: lower upfront costs, minimal business disruption, and long-term energy savings. However, the success of your project depends entirely on the contractor you hire. Proper preparation, material selection, and application are what make a coating last for decades instead of a few years.

At Pressure Point Roofing, we have spent 35 years mastering commercial roof restoration throughout Oregon, Southern Washington, and Northern California. We understand our region’s climate and how to apply the right systems for lasting performance. Our team partners with you to protect your investment with solutions backed by manufacturer certifications and decades of hands-on experience.

Ready to see if a roof coating is right for your property? Contact us today to schedule a comprehensive inspection and learn how professional roof restoration can benefit your building.

Learn more about our comprehensive Commercial Roofing services.

Schedule a Consultation

By submitting this form, I agree to receive calls and text messages (including those sent using automated technology) from Pressure Point Roofing, LLC and its representatives at the number provided. Message and data rates may apply. Message frequency may vary. Consent is not required as a condition of purchase. Reply STOP to unsubscribe at any time.

Related Content

Partners and Awards