Beyond the Slope: Uncovering the Secrets of Flat Roof Design

The Modern Appeal of Flat Roofs

Flat roof design is a versatile architectural choice offering a clean, contemporary aesthetic while maximizing usable space. Contrary to their name, flat roofs aren’t truly flat; they feature a slight slope (typically 1/4 to 1/2 inch per foot) for proper water drainage. These designs are cost-effective, easier to access for maintenance, and create opportunities for rooftop patios, gardens, or solar panels. A successful flat roof depends on the right waterproofing membrane, proper slope, and regular inspections.

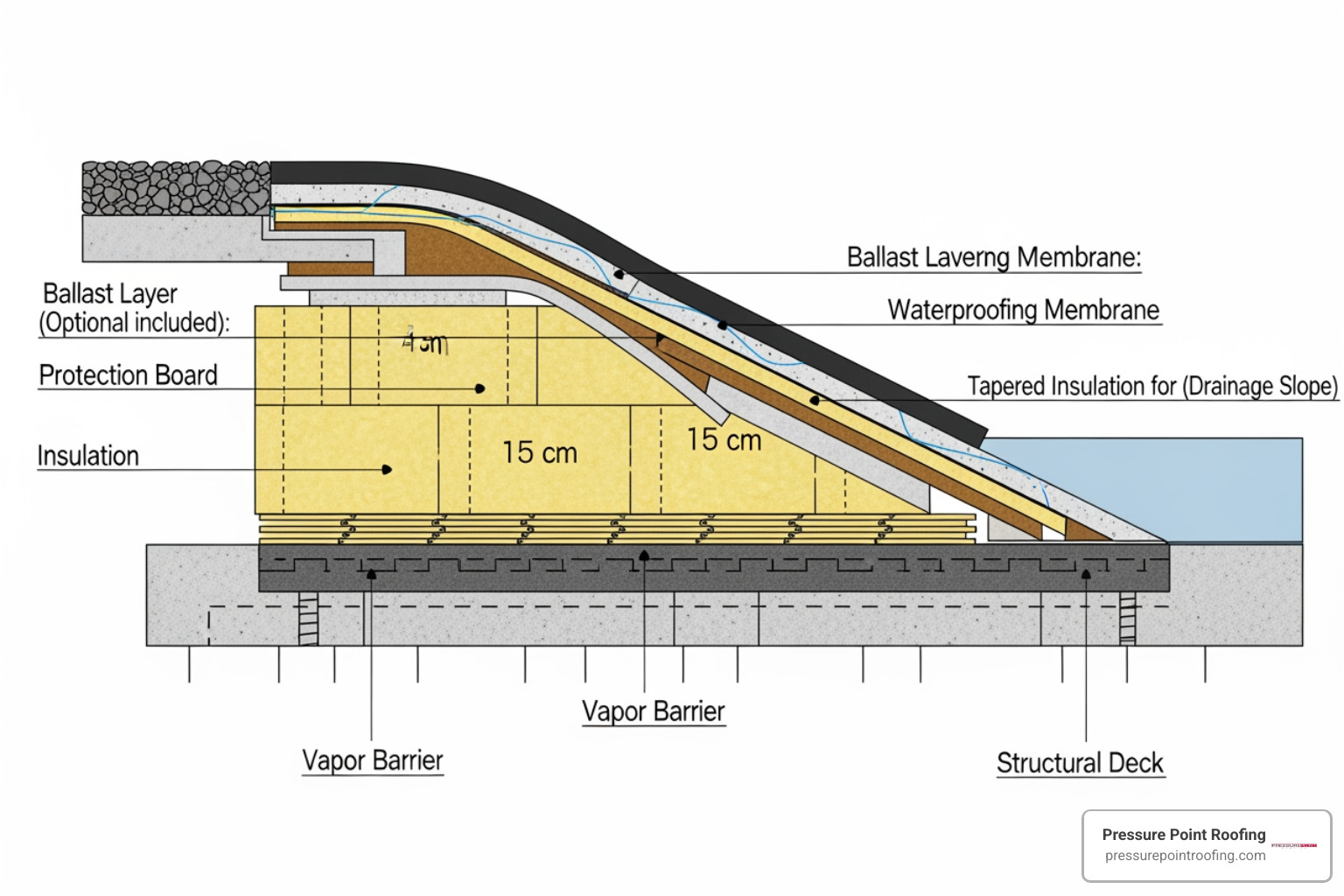

Key Components of Flat Roof Design:

- Structural Deck: The plywood or OSB foundation.

- Vapor Barrier: Prevents moisture from entering the roof assembly.

- Insulation: Improves energy efficiency.

- Waterproofing Membrane: The critical barrier against water (e.g., EPDM, TPO, PVC).

- Drainage System: Gutters, scuppers, or interior drains to manage runoff.

- Slight Slope: A minimum of 1/4 inch per foot to prevent ponding water.

For property owners in the Pacific Northwest and Northern California, a robust flat roof design is essential to handle the region’s heavy rainfall. A well-designed system can outlast three conventional asphalt shingle roofs, but improper installation or maintenance can lead to costly repairs. Understanding the system’s anatomy and climate-specific best practices is key to making an informed decision for any new build, extension, or commercial property.

With over 38 years in the roofing industry, I’m Larry Sykes, Director of Sales and Marketing at Pressure Point Roofing. I’ve seen how proper planning and material selection create roofs that perform for decades.

The Anatomy of a Flat Roof System

A flat roof design is a sophisticated, multi-layered system where each component works in harmony to keep your building dry, comfortable, and energy-efficient. Unlike a pitched roof that relies on gravity, a flat roof is an engineered assembly where every layer is critical.

When one component fails, the entire system can suffer. For a deeper understanding of how these systems differ from pitched roofs, read our guide on the 4 Main Differences Between Pitched and Flat Roofs. To learn what can go wrong, check out What causes problems in commercial roofing systems?.

Essential Components of a Modern Flat Roof Design

Every successful flat roof design is built upward from a solid foundation.

- Structural Deck: The base of the roof, typically plywood or oriented strand board (OSB). It must be strong enough to support roof materials, snow loads, and maintenance workers.

- Vapor Barrier: Placed above the deck, this layer stops warm, moist air from inside the building from penetrating the roof assembly, where it could condense and cause rot, mold, and damage to insulation.

- Insulation Layer: Usually rigid foam boards (PIR, XPS, or EPS), this layer improves energy efficiency and helps prevent condensation by maintaining consistent temperatures within the roof assembly.

- Waterproofing Membrane: This is the primary defense against rain and snow. Whether it’s EPDM, TPO, or PVC, this flexible, durable layer must be installed correctly to prevent leaks.

- Drainage System: Internal drains, scuppers, or gutters are essential for moving water off the roof before it can pool. Good drainage design is critical to preventing ponding water, the enemy of any flat roof.

- Flashing: This material seals vulnerable transition points, such as around pipes, vents, and where the roof meets a wall. Most leaks start at flashing points, so proper installation is non-negotiable.

Warm Roof vs. Cold Roof: A Critical Distinction

The placement of insulation in a flat roof design creates two distinct types: “warm roofs” and “cold roofs.”

In a warm roof, insulation is placed above the structural deck, keeping the entire roof structure within the building’s warm envelope. This prevents condensation from forming on cold surfaces, protecting the deck from rot and moisture damage. We recommend this approach for almost every project in our region due to its reliability and superior performance.

A cold roof places insulation between the joists, leaving the structural deck exposed to outdoor temperatures. This design requires a ventilation space above the insulation to remove moisture, but achieving adequate ventilation is notoriously difficult. Any failure in ventilation can lead to condensation, rot, and hidden structural damage. Given our wet winters in Oregon, Southern Washington, and Northern California, warm roof systems are the more reliable and durable choice.

Choosing the Right Waterproofing Membrane

The waterproofing membrane is the workhorse of your flat roof design, taking the brunt of rain, sun, and temperature changes. Choosing the right one is critical for long-term protection. Today’s single-ply membranes are lightweight, durable, and sustainable, with some materials being up to 80% reusable. A quality flat roof can easily outlast three conventional asphalt shingle roofs, which is why this choice is so important. We evaluate membranes based on durability, installation method, energy efficiency, and sustainability.

| Membrane Type | Durability | Installation | Energy Efficiency | Pros | Cons |

|---|---|---|---|---|---|

| EPDM | Excellent (50+ yrs) | Adhered, mechanically attached, or ballasted; glued seams | Low (black absorbs heat) | Flexible, durable, easy to repair, cost-effective | Black surface absorbs heat (unless white-coated), seams are glued (potential weak points if not installed well) |

| TPO | Very Good (20-30 yrs) | Heat-welded seams | High (reflective white) | Energy-efficient (cool roof), UV/chemical resistant, strong heat-welded seams | Can be more brittle in extreme cold, quality varies by manufacturer |

| PVC | Excellent (20-30 yrs) | Heat-welded seams | High (reflective white) | Highly chemical/fire resistant, durable, strong heat-welded seams, resistant to punctures | More expensive, can be rigid in cold, some environmental concerns with manufacturing |

EPDM (Ethylene Propylene Diene Monomer)

Often called “rubber roofing,” EPDM is a synthetic rubber membrane known for its remarkable durability and flexibility. It handles extreme temperatures and UV radiation well, and its large roll size means fewer seams. However, those seams are glued, which can be a weak point if not installed by experienced professionals. While traditional black EPDM absorbs heat, white-coated options are available to improve energy efficiency.

TPO (Thermoplastic Polyolefin)

TPO is one of the fastest-growing membranes for flat roof design because it balances performance, energy efficiency, and value. Its standout feature is heat-welded seams, where panels are melted together to create a monolithic, watertight bond that is often stronger than the membrane itself. TPO’s naturally reflective white surface makes it a “cool roof” that reduces cooling costs, a significant benefit in areas like Northern California. The technology is similar to what’s discussed in our article on Duro-Last Single-Ply Roofing Membrane: Features & Benefits.

PVC (Polyvinyl Chloride)

PVC is a premium single-ply membrane, ideal for projects requiring maximum durability and resistance to chemicals, grease, and fire. Like TPO, it features strong, heat-welded seams. Its exceptional toughness makes it a great choice for roofs on restaurants or industrial facilities and those with heavy foot traffic. While the initial investment is higher, its longevity often makes it cost-effective. Learn more in Why is PVC a good flat roofing material?.

Other Material Options

While single-ply membranes are popular, other systems are proven choices for specific needs.

- Built-Up Roofing (BUR): The classic “tar and gravel” roof, BUR consists of multiple layers of bitumen and reinforcing fabrics. It’s incredibly durable and fire-resistant but also heavy and messy to install.

- Modified Bitumen: An evolution of BUR, this asphalt-based membrane is reinforced with polymers for improved flexibility. It offers strong waterproofing and is well-suited for roofs with regular foot traffic.

- Liquid-Applied Membranes: These coatings are applied as a liquid and cure to form a seamless membrane. They are excellent for complex roof shapes and for restoring existing roofs, as they eliminate all seams.

Critical Considerations for Your Flat Roof Design

A durable flat roof design requires more than just a good membrane; it demands careful attention to structural integrity, drainage, and local climate factors. From rainy Portland to sunny Northern California, our climate demands adaptable solutions. For more on comprehensive solutions, visit our Commercial Roofing page.

Achieving Proper Slope and Drainage

No roof should be truly flat. We adhere to the industry standard minimum slope of 1/4 inch per foot to ensure water flows effectively toward drainage points. This slight incline is crucial for preventing “ponding water”—standing water that remains for more than 48 hours and can accelerate membrane degradation and cause leaks.

An effective drainage system is equally important. Options include:

- Gutters: Mounted along the roof’s edge to collect and direct water to downspouts.

- Scuppers: Openings in parapet walls that allow water to drain off the edge.

- Interior Drains: Located within the roof field, they channel water through pipes inside the building.

Regardless of the system, regular debris removal is essential to prevent clogs and water backup.

Designing for Your Climate

A flat roof design must be engineered for local weather challenges across Oregon, Southern Washington, and Northern California.

- Snow Loads: The roof’s structure must be designed to bear the weight of accumulated snow, meeting or exceeding local building codes.

- High-Wind Zones: To resist wind uplift, we use robust fastening patterns, fully adhered membranes, and sealed roof decks, ensuring compliance with ASCE 7 standards.

- UV Exposure: In sunny areas, we select UV-resistant membranes like TPO and PVC or apply reflective coatings to extend the roof’s lifespan.

- Temperature Fluctuations: Materials and installation techniques must accommodate the expansion and contraction caused by temperature swings to prevent cracking and seam separation.

We ensure every aspect of the design complies with local building codes, which dictate everything from structural requirements to insulation values. For more on weather preparation, see our insights on Winter Weather Commercial Roof.

Longevity, Maintenance, and Functional Design

A well-designed flat roof design offers exceptional longevity—EPDM can last 50+ years, while TPO and PVC provide 20 to 30 years of service. Achieving this lifespan hinges on consistent maintenance. Beyond protection, flat roofs also offer exciting opportunities to create usable space. For guidance on maintaining your roof, explore our Tips for Commercial Roofing Maintenance.

Essential Maintenance and Inspection

Regular maintenance is non-negotiable for preserving your flat roof design. We recommend professional inspections at least twice a year (spring and fall) and after major storms. Key checks include:

- Debris Cleaning: Clear leaves, branches, and dirt that can block drains and trap moisture.

- Drainage System Check: Ensure gutters, scuppers, and drains are clear and functioning properly.

- Seam Inspection: Look for any separation, lifting, or cracking in membrane seams.

- Flashing Check: Inspect seals around vents, skylights, and walls for damage or gaps.

- Membrane Integrity: Examine the surface for punctures, tears, or blisters.

For more details, refer to our article on Fall Commercial Roof Inspection.

Preventing and Addressing Common Problems

Even durable roofs can develop issues if neglected. Be aware of these common problems:

- Ponding Water: Standing water that remains for over 48 hours is a red flag. It’s prevented by proper slope and clear drains.

- Leaks: Often stemming from damaged flashing, compromised seams, or punctures. Prompt professional repair is crucial.

- Blistering: Trapped air or moisture can form bubbles. While small blisters may be harmless, large ones should be inspected.

- Seam Separation: Glued seams can degrade over time. Heat-welded seams are more robust but still require inspection.

Proactive maintenance is the best defense. Learn more in Prevent Roof Rot with Regular Roof Maintenance and how to handle existing issues in Leaking Commercial Roof.

Specialized Flat Roof Design for Usable Spaces

One of the greatest advantages of a flat roof design is changing unused areas into functional spaces.

- Rooftop Patios and Decks: A popular way to add outdoor living space. This requires improved structural support, robust waterproofing, and protective decking layers.

- Green Roofs: Covering the roof with soil and plants improves insulation, manages stormwater, and adds beauty. These systems require specialized drainage layers, root barriers, and a structure that can support the added weight.

- Solar Panel Installation: Flat roofs are ideal for solar arrays. Installation requires careful consideration of structural capacity and often uses non-penetrating mounting systems to protect the waterproofing membrane.

Integrating these features adds significant value. If adding access points, consult our guide on What you need to know about skylights.

Frequently Asked Questions about Flat Roof Design

Here are answers to some of the most common questions we receive about flat roof design.

How long does a flat roof last?

The lifespan of a flat roof depends on the material, installation quality, and maintenance. A modern flat roof design is incredibly durable: TPO or PVC membranes typically last 20 to 30 years, while EPDM can exceed 50 years. A well-maintained flat roof can outlast three conventional asphalt shingle roofs. However, achieving this longevity requires regular inspections and timely repairs to mitigate the effects of climate and foot traffic.

Are flat roofs more prone to leaks than pitched roofs?

This is a common misconception based on outdated technology. A modern flat roof design, when professionally installed, is just as watertight as a pitched roof. Leaks are prevented by three key factors: a slight slope (no roof is truly flat), an effective drainage system, and advanced waterproofing membranes. Problems arise only when a roof is installed without a proper slope or when drains are allowed to clog, leading to ponding water. With expert design and regular maintenance, your flat roof will remain leak-free.

Can a flat roof be installed in a heavy snow or rain climate?

Yes. We regularly install flat roofs throughout Oregon, Southern Washington, and Northern California, regions known for heavy rain and snow. A successful flat roof design in these climates requires several key elements: proper slope (at least 1/4 inch per foot), a robust waterproofing membrane with expertly sealed seams, and a structure engineered to handle local snow load requirements. A drainage system designed for heavy rainfall and a warm roof system to prevent internal condensation are also critical. When these components are correctly integrated, a flat roof performs beautifully in any weather.

Conclusion: Accept the Possibilities of Modern Roofing

Modern flat roof design is an engineered system that offers a sleek aesthetic, cost-effective durability, and improved functionality. These roofs are not truly flat but are designed with a slight slope to manage water effectively. The key to a system that lasts for decades lies in choosing the right materials—like durable EPDM, energy-efficient TPO, or resilient PVC—and ensuring it is properly installed and maintained.

The beauty of a flat roof design is its potential. It can become a rooftop garden, a patio, or a platform for solar panels, adding value and usable space to your property. While challenges like ponding water can occur, they are almost entirely preventable with thoughtful design, professional installation, and consistent maintenance.

In Oregon, Southern Washington, and Northern California, your roof faces unique demands. With 35 years of experience, Pressure Point Roofing creates custom flat roof solutions built to withstand our diverse climate. If you’re ready to explore what a modern flat roof can do for your property, Contact us for your roofing needs and let’s start the conversation.

Schedule a Consultation

By submitting this form, I agree to receive calls and text messages (including those sent using automated technology) from Pressure Point Roofing, LLC and its representatives at the number provided. Message and data rates may apply. Message frequency may vary. Consent is not required as a condition of purchase. Reply STOP to unsubscribe at any time.

Related Content

Partners and Awards